Autochucks & Sub-assemblies

About Dental Handpiece Autochucks

Autochuck is another name for the push button spindle/chuck (collet) assembly which holds the dental bur and onto which the other components of the turbine cartridge (e.g. bearings, impeller) are attached or pressed. The ISO maximum specification for concentricity (run-out) is 0.0012 in. / 0.03 mm.

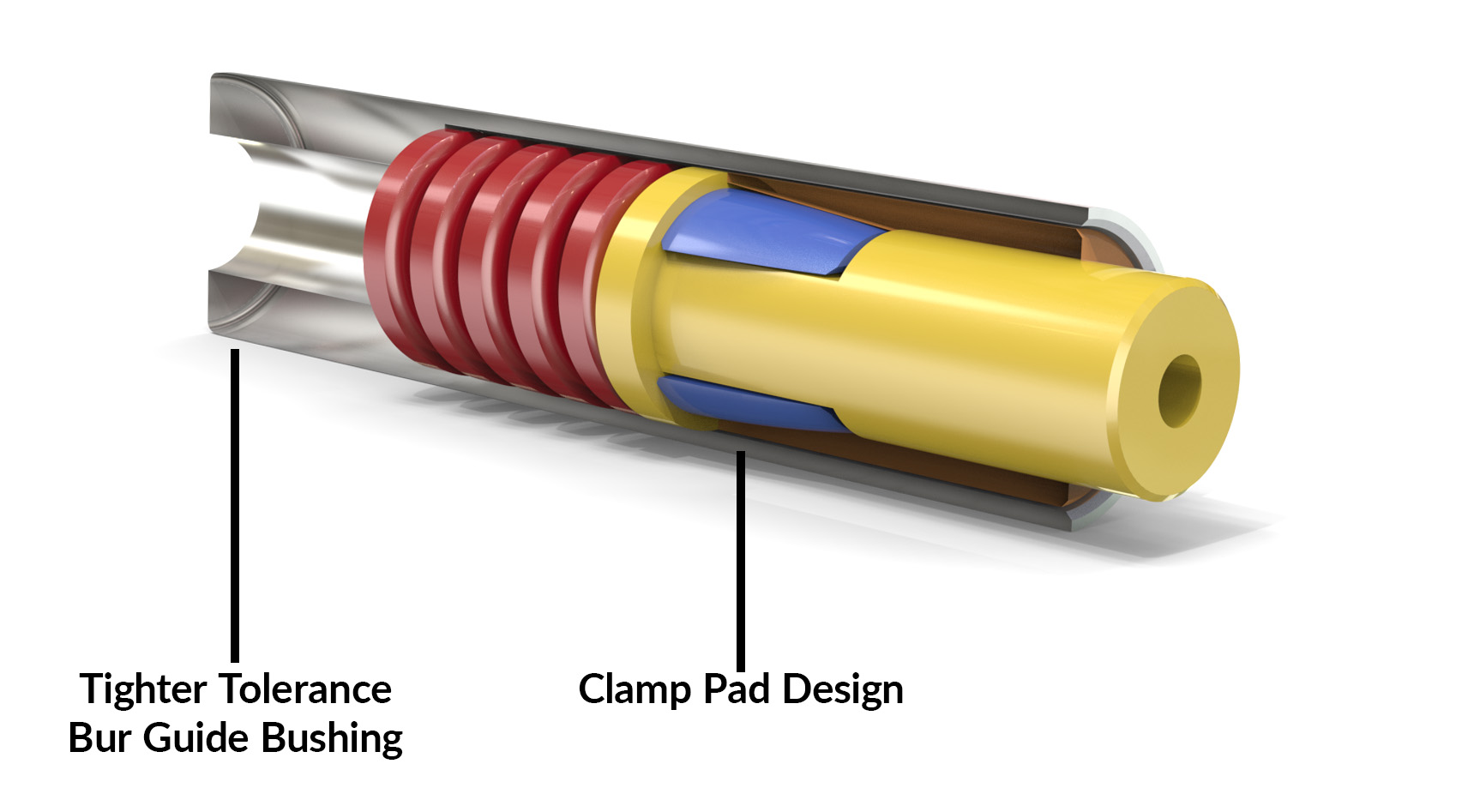

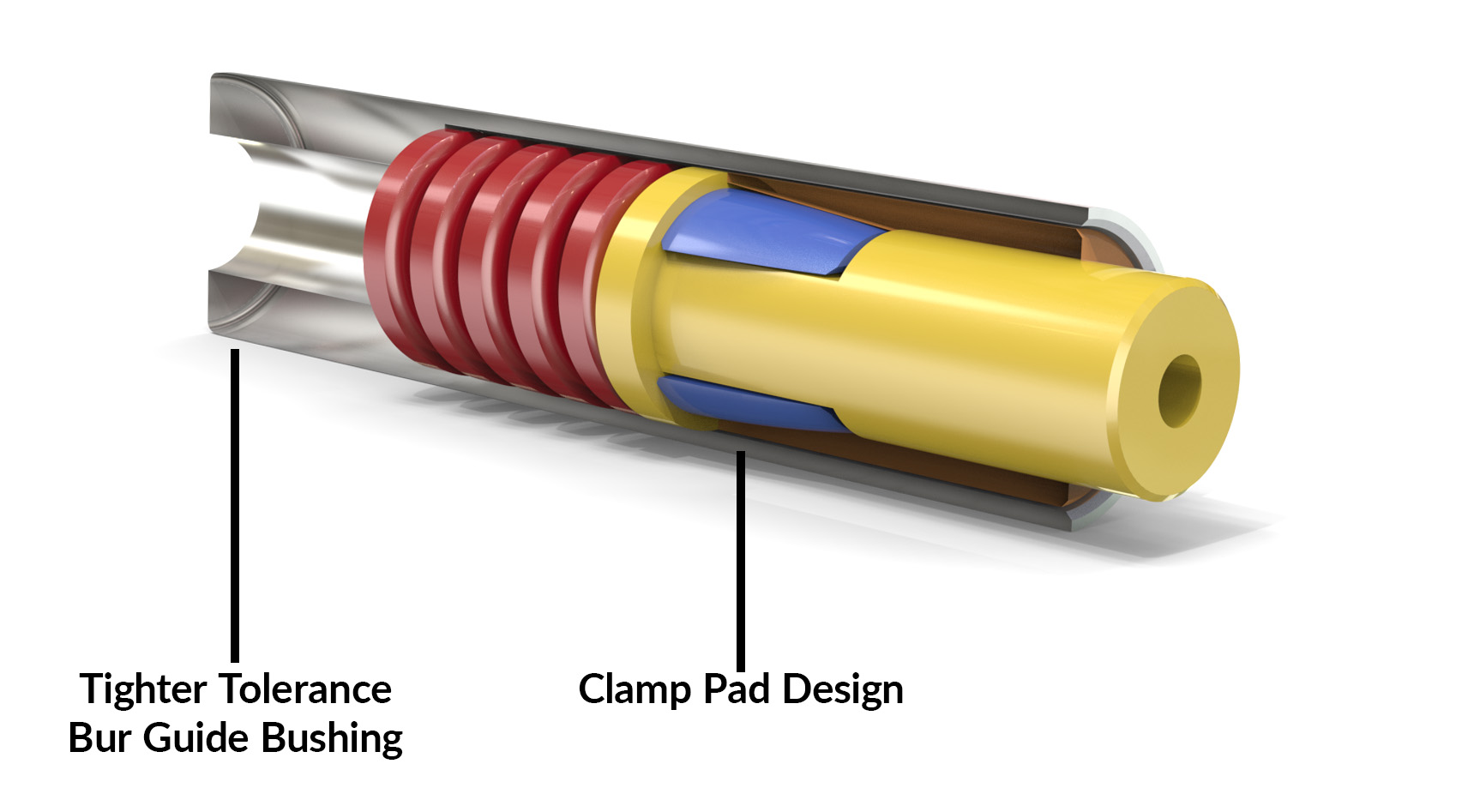

Two common autochuck designs are clamp-pad and wedge.

Extend dental sub-assemblies are designed to meet or exceed the OEM specifications for handpiece turbines. They offer premium features and an extended warranty for high speed turbine repairs.

- Optimized wedge angle = easier actuation

- Tighter tolerance on the bur guide bushing and collet = improved concentricity and longevity

- Carbide or a clamp pad design

- Improved heat treat specifications

- 100% precision laser balanced

- 15 month No Hassle Warranty

- Some custom configurations for individual models

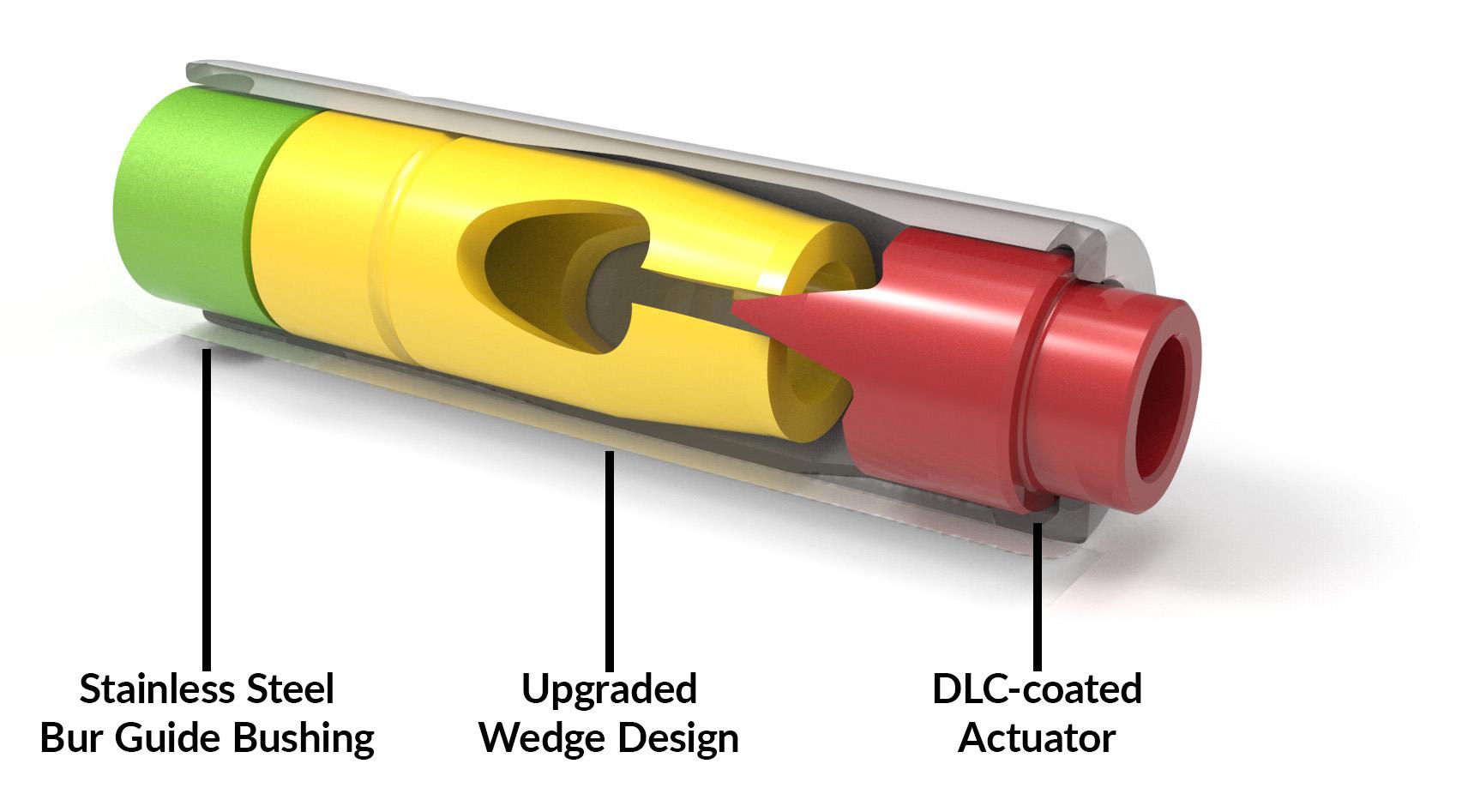

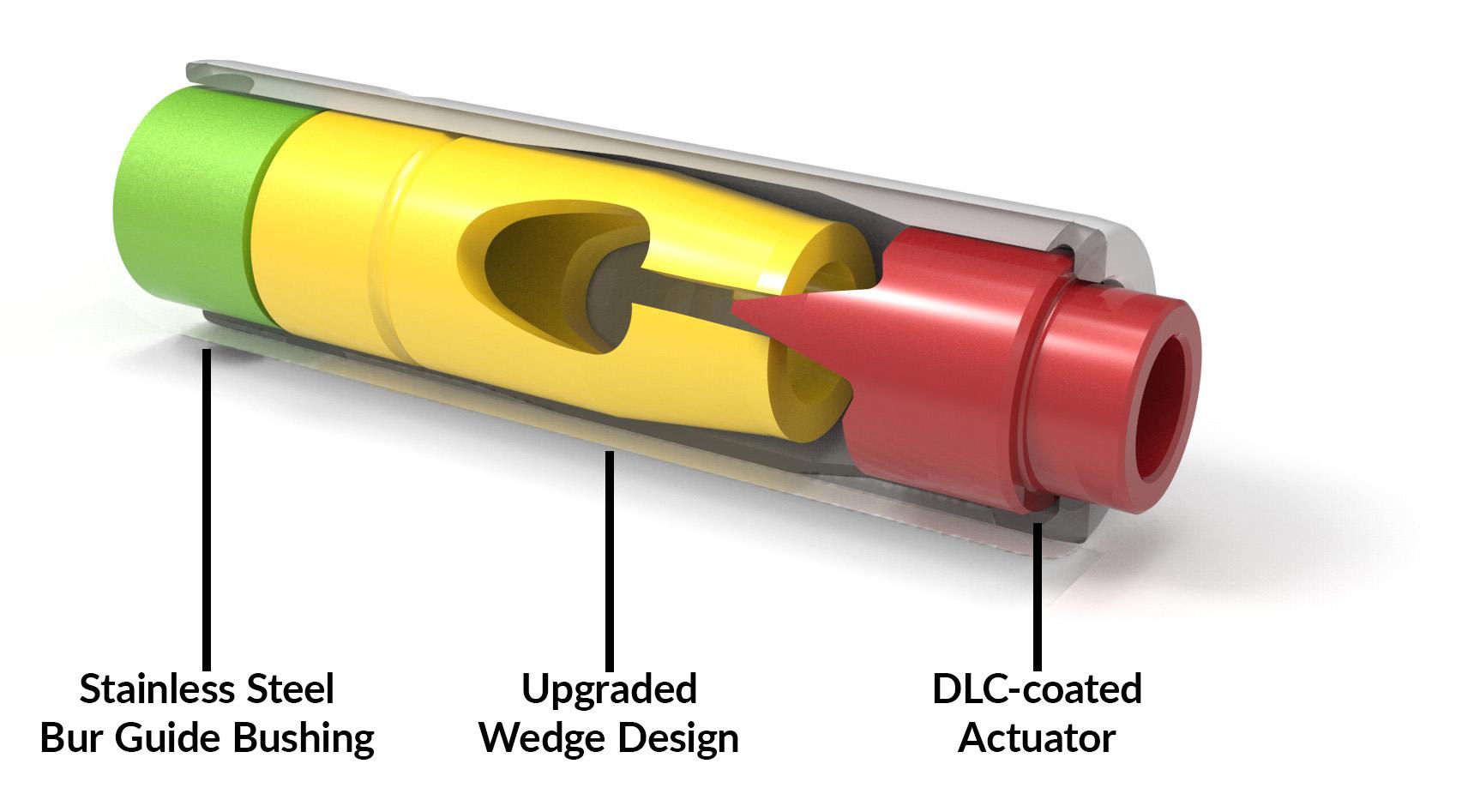

Our new Perfection line of dental sub-assemblies incorporates an upgraded autochuck backed by a 1-year warranty. They are a perfect fit for all high speed dental handpiece turbine repairs.

- 35% increased longevity over ValuPak

- Upgraded wedge design for enhanced clamping force & improved bur retention over time

- Automated laser balancing

- Automated assembly and inspection to ensure consistent quality

- State-of-the-Art manufacturing cell for impellers

- Stainless steel bur guide bushing improves bur concentricity and extend chuck life

- DLC coated actuator reduces chuck wear and prolongs life

- Heat-treated, precision-ground spindle with honing of critical dimensions

- EDM precision machined collet

- Individually serialized for traceability

- Available in single and multipack

- Some custom configurations for individual models